GST : 24ABMFM3684M1ZN

- New Arrivals

- Featured

We are qualified manufacturers, suppliers, and exporters of various process plants & heavy industrial equipment having all the necessary infrastructure in-house to manufacture the equipment. Since its establishment in 1986, the company has witnessed strong and steady business growth. The strength of Mech Engineers lies in trustworthy, well-experienced, and qualified personnel, machinery, infrastructure, and supplier network to meet Quality Standards and Delivery Schedules at the most competitive rates.

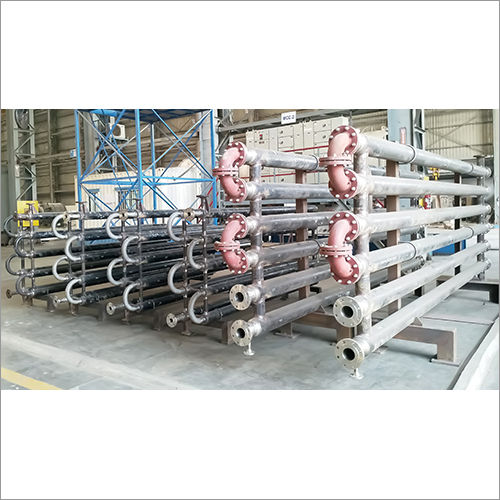

We serve the needs of petrochemicals, agro-industries, pesticides, pharmaceuticals, process industries, bulk drugs, dyes/paints, steel mills, paper/pulp, chemicals, and energy industries by supplying static and rotary equipment like, Heat Exchangers With Expansion Joints, Custom Built Heat Exchanger, Seawater Desalination Condenser Heat Exchanger, Industrial Autoclave, Liquefied Gas Storage Tank, Receiver Tank, etc., which meet the requirements of national and international standards & codes like Indian standards (ISI), ASME, DIN, BRITISH, TEMA, API & ASTM, etc. Mech Engineers holds an authorization from the American Society Of Mechanical Engineers (ASME) to apply the U stamp on Pressure Retaining Components, Heat Exchangers, constructed at the companys workshop. Our company is ISO 14001:2015 certified and iso 45001:2018 certified. We can handle materials like carbon steel, stainless steel, copper, aluminum, nickel, Hastelloy, etc.

Company Policy

We are committed to achieving customer satisfaction by providing quality products on time, which is achieved by employee involvement with teamwork, effective utilization of resources and continually improving the effectiveness of the quality management system.

Environment Policy

We Mech Engineers are committed to being an eco-friendly organization. We promise to protect, preserve and improve our environment by preventing and minimizing pollution of air, etc. This we achieve through:

- Continual improvement of the Fabrication Process to reduce wastes and pollution for maintaining better environmental conditions

- Optimizing the usage of energy and all other resources. Wherever possible, solar energy is utilized to the maximum extent

- Ensuring proper disposal of wastes to reduce the impact on the environment

- Complying with legal and other requirements

- Implementing and improving safety standards

- Creating environmental awareness among the employees to facilitate the implementation of the policy

- Maintaining a green environment through the plantation of trees to ensure beautiful surroundings.

- By effectively implementing the above, Mech Engineers is proud of being a responsible organization contributing to social welfare.

Infrastructure

Our manufacturing unit is well-equipped with all the necessary tools and technology needed for the production of our products like, Custom Built Heat Exchanger, Heat Exchangers With Expansion Joints, Seawater Desalination Condenser Heat Exchanger, Industrial Autoclave, Liquefied Gas Storage Tank, Receiver Tank, etc. We have all the necessary testing machines, on which every product is tested before it is delivered to our clients.

Miscellaneous & Testing

All types of measuring equipment are available with us. Radiography Viewing Machine and dark room facility are available with NDT Level II Personnel. Computers with Pittee make drafting machine along with AutoCAD facilities including Hydraulic Testing Pump are our other testing facilities.

Clients

We serve the following industries

- Chemical plants

- Dairy

- Steel

- Petrochemicals

- Pharmaceuticals plant

- Paper & pulp

- Bulk drugs

- Fertilizers

- Pesticides

- Agro industries

- Foods

- Distillation plants.

Quality

Mech Engineers prides itself on its uncompromising quality standards. the Quality department is employed sophisticated equipment and techniques to ensure the quality of all materials. Stage inspections are carried out to ensure welding and dimensional accuracy. Reputed laboratories/industrial services are attached to Mech engineers for carrying out physical & chemical testing of materials, all NDT & heat treatment facilities.

Our Motto

The motto of our company is first to assure quality & then after production. Our equipment manufactured under high-quality control measures give the best refund and is durable.

Download Brochure

|

MECH ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry